The shed and yarding system on a deer farm must be designed and constructed to provide a safe and practical work environment for both animals and the operator. Deer are inherently flighty animals especially when stressed, and can become unpredictable when handled. It is therefore important that sheds, yards, and races are designed to eliminate the chance of injuries.

A great set-up will provide an efficient flow of deer from their paddock, through the race, yards and shed, allow them to undergo their various treatments and be back out grazing in the paddock in as little time as possible, without a fresh carpet of deer hair shed onto the floor.

Good yards save time and money because they result in:

- less stress on deer (stressed deer = reduced production)

- less stress on the operator (more enjoyable working environment)

- reduction in labour costs (personnel spend less time struggling to handle deer in inappropriate yards, labour costs are probably the single biggest cost in deer farming)

- reduced chance of injury to the handlers in the sheds, and the animals

- increased property value

It is recommended that if you are planning on building a deer shed and yard facilities from scratch that you go and visit other facilities to see which systems work best.

A deer yard and shed facility is a place of work, and as such there is a legal responsibility to provide a safe working environment for the people using it. Number one priority is to eliminate serious injuries. An appropriate Health and Safety system which identifies, eliminates or controls hazards that are apparent on deer farms is essential.

The people that are strictly responsible for managing hazards and providing a safe work environment for those people working with animals is covered in the Health and Safety Employment Act 1992 (section 16): The owner, lessee, sub-lessee, occupier, or person in possession of a place of work, and people in the vicinity of the place of work, that they are not harmed by any hazard that is or arises in the place of work.

There are also regulatory requirements of a deer shed that relate to animal welfare and can be found in the animal welfare codes of practice, more information on shed design can be found in the following section: welfare codes and industry agreed standards >>

The minimum standards of a handling facility as required by the Deer Code of Welfare (2018) issued under the Animal Welfare Act 1999 are as follows:

- Facilities must be designed, constructed and maintained to prevent injury to animals during routine husbandry procedures.

- All protrusions, gaps and edges, including damaged flooring, likely to cause injury to deer must be removed, repaired or covered.

- The storage of all health remedies, toxic materials and associated equipment must be secure and inaccessible to deer.

- Ventilation must be sufficient to prevent a build-up of excessive heat, humidity and noxious gases.

- All deer facilities must have light at a minimum of 20 lux available at all times to enable safe inspection and handling of animals.

- All power cables and associated fittings must be inaccessible to deer.

- Floors must be constructed of non-slip material.

More information and recommended best practice advice on handling facilities can also be found in the welfare code >>

There are also separate minimum standards set in the code to cover holding facilities. Holding facilities are used by farmers to hold deer for short periods of time to carry out specific activities, e.g. quarantine, weaning, weighing, on-farm sales, etc. The minimum standards from the Deer Code of Welfare (2018) are as follows:

(a) Facilities must be designed, constructed and maintained to:

(i) allow ready access to handling and inspection of deer; and

(ii) enable segregation and treatment of any deer; and

(iii) enable ready evacuation in the case of emergencies.

(b) Where deer are held in facilities for periods of more than 24 hours, a sufficient area of dry bedding within the holding facilities must be available to allow all deer to rest by lying down.

(c) Ventilation must be sufficient to prevent a build-up of harmful concentrations of gases such as ammonia and carbon dioxide.

(d) If ammonia levels of 25 ppm or more are detected within the holding facility, immediate and appropriate action must be taken to reduce the ammonia levels.

(e) Where deer do not have access to natural daylight, a minimum of 8 hours and a maximum of 16 hours of continual artificial daylight (minimum 50 lux) must be provided.

(f) During inspection periods, natural or artificial light of at least 20 lux must be available at the level of resting deer in all holding facilities.

(g) Water supply systems must be well protected to ensure that the risk of flooding, loss of supply or fouling is minimised.

(h) All sharp objects, protrusions and edges, including damaged flooring likely to cause injury to deer, must be removed, repaired or covered.

(i) Any electrical fittings and attachments to mains voltage must be out of the reach of the deer, or protected from interference or damage by the deer.

(j) To minimise aggression and injuries, additional care must be taken when male deer with hard antlers are held in holding facilities.

(k) Deer must not be released from a prolonged period indoors without ready access to shelter and shade in adverse weather to avoid temperature stress.

(l) All deer must have enough space to be able to lie down, rise and stand comfortably without undue risk of stress or injury to themselves or other animals.

(m) Ceiling heights must be at least 2.4 metres.

Again, additional information can be found regarding best practice recommendation of deer holding facilities within the code.

The site of the deer shed on a farm must be carefully considered. If put in the wrong place then there is every good chance that mustering the deer into the sheds and yards will always be an ordeal.

The following suggestions or tips for good shed design should be considered:

- Good drainage is essential, therefore the shed and yards should ideally be sited on a natural rise, or on elevated ground.

- Deer yards should be sited away from noisy traffic situations.

- The load out race should be situated in a place that is easily accessible for the transport trucks in all weather conditions. A good vehicle track leading to the shed is essential.

- There may be local restrictions for building consents or permits required for constructing a deer shed. Similarly restrictions can be imposed by local authorities as to the position of the load out race to roads, and road verges. Advice should be sought from local authorities before construction.

- Power to the shed for lighting and the use of powered equipment such as hydraulic crushes, or deer clippers should be planned. Power can also be provided by a portable generator. Note: deer should not be allowed access to power cables. They may chew the cords and risk being electrocuted.

- Running water is necessary to provide a means of hosing out the facility.

The lead-in race to the shed should be easily accessed from the farm's central race. The following design features are recommended for an effective lead-in race:

- The race should be 3-4 metres wide and start to narrow once the yards are reached.

- It is recommended that the lead-in race be covered in a solid material, e.g. shade cloth, or be densely planted with shrubby trees or flaxes. Deer have been known to break their necks by hitting netting at an acute angle when running down a race. The other advantage of creating a solid barrier is that the lead-in race, or lane appears to be an escape corridor for the deer which aids deer flow into the yards. Only non-toxic planting species should be used.

- The gate into the yards should be of very strong construction, be a minimum of 2 metres high, and be easy to close quickly. It is recommended that the top hinge gudgeon be installed upside-down to prevent the gate from being lifted off its hinges. The latch must be strong. Deer often get spooked as they encounter the shed and often try and escape or stampede back out into the lane en masse, which is incredibly dangerous to the person trying to latch the gate closed. It is recommended a strong, galvanised, quick self-latching latch be purchased from any farm supply merchant for this purpose. Slow to close and clumsy chains or hooks are not to be used!

There are many types of deer shed designs being used in NZ, however there are some poorly designed sheds that are essentially danger traps. The following examples of shed design are ones that have features that provide a safe working environment when handling deer, and have practical layouts for ease of use and good deer flow.

- It is advisable to split large mobs in the holding or receiving yards before the mob enters the shed. This makes them easier to handle, but reduces safety concerns for both animal and handler. A large mob of panicked or stressed deer can become very hazardous to handle, but also deer injuries become more common.

- Large mobs of deer in a yard or shed are more likely to try and assert a pecking order amongst themselves, and may start to fight. It is advisable to only bring in small mobs of deer into the shed. And split larger mobs into approximately 12-20 animals per group.

- Only compatible animals should be penned together.

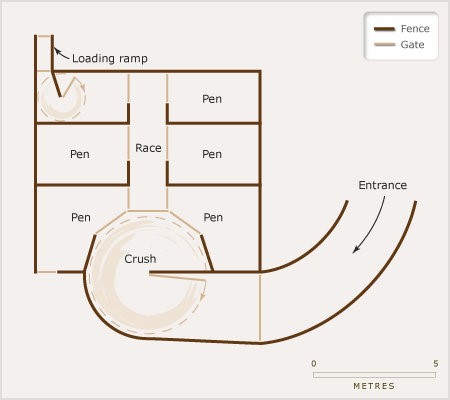

- The circular yard plan works extremely well when handling deer. Deer have a longer flight distance than other animals, i.e. the try and run away from you at every chance they can get. The circular yard therefore works well with deer, because the deer will move naturally around the corner to try to move away from the handler. They also provide many options for sorting out or drafting deer by providing many pens, and gate setups. And they are also relatively easy to build. Below is an example of a circular yard and shed system (AgriQuality Safe Practical Deer Yards, 2005).

- Rectangular yards also work well, provided the same prinicples of good deer flow are adhered to. Any corners should be boarded off at 45 degree angles, so that deer do not congregate or pile up in corners. It is inadvisable to use railing with large gaps as this provides a great ladder like structure for deer to climb up and make their escape. Below is an example of a rectangular yard (www.teara.govt.nz).

Other good design features of a deer shed include:

- When planning a new shed, the overall layout must me practical for the operator, special consideration needs to be placed on what areas are to be used for what purposes or end use, e.g. if velvetting or artificial insemination is to be carried out in the shed, then these places must have adequate light and be able to be easily cleaned to maintain hygiene.

- Any animal health remedies, e.g. drenches or velvetting drugs must be contained in a lockable cupboard within the shed.

- A first aid kit and emergency response system, e.g. in case of injury, or accidental injection of velvetting drugs, must be clearly displayed.

- A clearly displayed emergency response sign should be included in every shed with phone numbers, and emergency contacts clearly visible. All workers in the shed should have first aid knowledge, and know which phone numbers to dial in case of emergency.

- The utilisation of natural light at strategic places to encourage movement of deer through the shed. This is because the lightened area looks like a clearing that the deer will naturally move towards.

- Natural lighting can be provided by incorporating clear poly-carbonate sheeting in the roof over the working areas.

- Good ventilation is essential in deer sheds, it is common for temperatures to rise to dangerous levels especially in summer, and this becomes a welfare issue for the stock, and is very uncomfortable to work in. There is information within the welfare code related to ventilation and temperature levels within sheds.

- Provide adequate lighting and good ventilation, however it is recommended that deer contained within the shed are not able to see deer leaving the shed, or deer outside in paddocks or holding yards.

- Concrete floors can be installed in the shed after the yard and race posts are installed, and before walls are constructed.

- A slight gradient sloping to a natural drainage point is recommended, the drain must be adequate to enable the shed to be hosed out when required.

- Regular cleaning of the flooring is recommended due to the risk of ammonia build-up where ever the deer are being held.

- A slight gradient leading through a shed also encourages deer to flow through it as deer will move naturally up-hill better.

- Scoring the concrete is recommended to produce a non-slip surface.

- The forcing pen areas and race should be covered and weather-proof to provide a dry working environment. A muddy floor becomes very hazardous in these areas, and is difficult to work in.

- The materials used in construction need to be strong and robust enough to handle the severe knocks received from confined deer.

- A minimum of 2 metres is recommended for gates and internal shed walls to prevent animals from jumping out and escaping.

- Smooth walls with no sharp corners that could cause injury or bruising. Plywood or second hand conveyor belting are good lining products. As is macrocarpa boards (150mm x 20mm) running horizontally with 100mm gaps between.

The internal race within a shed is designed to facilitate various treatments so that they occur safely. This includes: TB testing, blood testing, vaccinating, drenching, pregnancy scanning, ear tagging, weighing, etc. The operator is located on the outside of the race to ensure safety and reduce the risk of accidents.

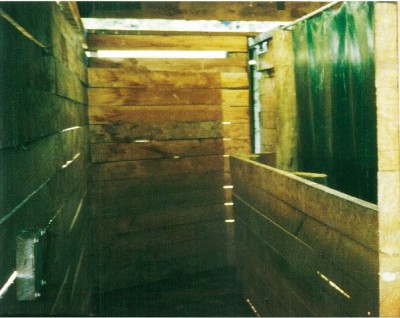

A plastic canvas race curtain is an effective design feature of the internal race as it allows the operators to work on the inside of the curtain beside the race without letting light into the area. The deer are therefore unable to see any escape route.

Please note: this type of race is not recommended for administering treatments to unruly or aggressive stags (especially wapiti stags). These types of animals can deliver severe head butts or injuries to the operator, and should only be treated in a crush or other restraint device that provides total head and body immobilisation.

See below for suggested construction of a plastic canvas race curtain (AgriQuality Safe Practical Deer Yards, 2005).

The internal race usually leads into a restraint system of some sort, more detail on these system in the following link: Restraint and weighing systems >>

Ideally the shed should also include a set of scales for weighing individual animals. Weighing produces many benefits to deer management as it is a key measure of productivity, growth and reproductive performance. A good set of scales that are placed in a strategic area of the yards are vital. Numerous systems have been proven to work effectively. Please see the external links to some commercial weighing websites.

- Gates need to be of strong construction and made out of material that won't sag and be robust enough to take severe knocks.

- It is recommended that the panels are smooth, i.e. no gaps, to prevent deer from climbing up them to escape, or get their feet caught.

- Hinges must be strong and secure. To prevent the gate from being lifted off its hinges by milling deer, the top gudgeon should be reversed, or a four inch nail can be driven at right angles above the bottom hinge. Some hinges are constructed with a retaining pin which can be used with or without a padlock.

- Sliding gates made out of a pipe frame and plywood, can also be used in the shed provided they strong and are quick and easy to operate.

The best features of a latch are that they are:

- strong

- quick and reliable to open and close

- unable to be accidentally opened by deer

- are not a potential hazard to deer or personnel

- wire or chain latches are not recommended as they are too slow to close, and can be a potential hazard if required to be used in a hurry.

Of most importance is the construction of escape doors. These enable a person to escape quickly and easily from each pen when confronted with a charging or aggressive animal. These doors are narrow to prevent animals from escaping but should not be less than 400mm, so the person using them can escape quickly. These doors are always unlatched and should be placed strategically in the forcing pen and also pens that have no other means of escape. The use of such doors are even more important when flat panels, e.g. plywood, are used as internal shed lining.

On sheds with high roofs, cat walks or suspended walkways can be installed on the outside of pens, or on top of the walls dividing pens. This means the handler does not need to be in contact with the deer, but still provides a means of controlling them. A good tool for moving the deer from pen to pen from these cat walks is to tie a plastic bag to the end of a long (2m) stick. The rustling sound is very effective!

- The load-out chute must be able to accommodate all types of deer transporter to efficiently and safely load deer onto the trailer/truck.

- A height adjustable ramp is useful to be able to meet the floor of different sized the trucks to facilitate loading. It also reduces the likelyhood of injury to deer when unloading because deer do not need to jump down to the ground.

- The sides should be solid so that deer can only see straight ahead into the truck.

- A loading chute for trophy stags needs to have special features such as: increased width (at least 2m) to enable a stag to move up the shoot with a full head of antlers, the chute also needs to be height adjustable.

Safety is the main concern when working with deer within a shed and yard facility, so it is vitally important that the shed is well designed and fit for purpose. It is also important that deer are handled in these facilities efficiently so that it is an enjoyable experience for the operator, and reduces the level of stress on the animals when handled.

Approach local deer farmers to gain learn about a deer operation to help you develop your farm layout. Races should be no more than 3–4m wide leading into the yards.

Easy flowing corners assist the flow into the yards, or baffles in a straight race. This gives the illusion that they are escaping from the musterer. In the last few metres before entering the yards where there is a higher pressure area, wooden rails or scrim assist smooth flow into the yards.

All boundary fences require 1.9m high netting with 2m high post spaced at 5–6m to provide a secure perimeter fence. Fallow deer are more likely to want to go under the fence but can easily jump a 2m fence if under pressure.

Depending on the size of the mob you plan to graze, having the appropriate number of paddocks gives you a satisfactory grazing rotation system. Also, taking into consideration the different groups of animals you plan to have on your property will determine the final design.

More resources

More detail can be found within the following websites:

Deer Farming Handbook from the Deer Industry Association of Australia, click here >>

Safe Practical Deer Yards. 2005. AgriQuality Limited, click here >>